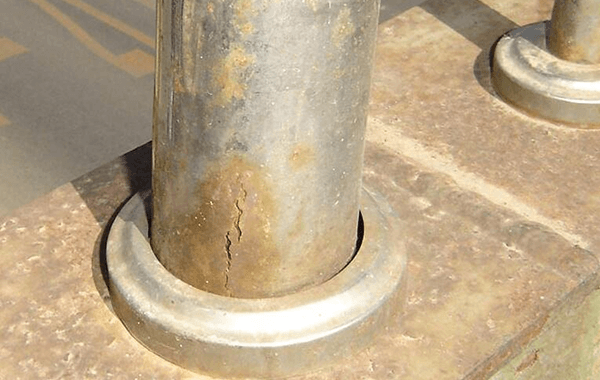

If enough oxygen is present to combine with the chromium in the alloy (and other conditions are right), the passive layer will "heal itself," which is one of stainless steel's major benefits. Once stainless steel processing equipment has been passivized and placed in service, the passive layer can be damaged by being abraded or through expansion or contraction caused by heating and cooling. Passive layer maintenance - when it self-heals, and when it doesn't Degreasers or other appropriate commercial cleansers should be used for an initial cleaning process. Fats react with acids to form gas bubbles that stick to the surface of the metal, interfering with passivation. While it might seem reasonable to assume that an acid bath would remove grease and other contaminants, it all gets back to the micro-level chemistry with corrosion. If not removed, these particles can compromise the passivation process and plant the seeds for corrosion. Other substances such as grease and coolant from the shop environment can land on the stainless steel parts. During the machining process, iron particles can abrade from the cutting tool and transfer to the surface of the stainless steel workpiece. It's also important to emphasize that a crucial first step - cleaning - is needed to eliminate contaminants that could compromise the passivation process. It should be noted, though, that citric acid itself doesn't do the passivation - but it does a superior job of preparing surfaces to spontaneously passivate in the ambient air. Using citric acid minimizes this potential for this detrimental removal, promoting a thicker oxide layer

The chromium combines with oxygen to form chromium oxide (Cr2O3 - two atoms of chromium and three of oxygen, though there is another form of chromium oxide with one atom of chromium and one of oxygen).Īlthough a passive layer forms naturally in alloys with a chromium content of between 10.5% and 12%, stainless steel equipment should be treated with a process called chemical passivation to ensure it's protected immediately and properly.Ĭitric acid is gaining on nitric acid for passivation use for several reasons: "Passive" basically means non-reactive, and that's what chromium does for steel - shields it from being chemically reactive and therefore corroding. Through a chemical reaction called passivation.

#DOES 316 STAINLESS STEEL RUST SERIES#

18/8 is actually included in the modern 300 series of stainless steels along with 304 and 316 stainless steels. Soon after, the formula of 18% chromium and 8% nickel added to iron began coming into ubiquitous use as 18/8 stainless steel for cutlery and cooking equipment. It was only when metallurgists added over 5% that they discovered that chromium prevented iron from rusting. Up to the early 20th century, chromium had only been added to iron in quantities of less than 5%. Chromium had only been isolated as a material about 50 years previously. During the Iron Age, which ended about 500 years BCE, iron was alloyed with carbon to make steel, and it was first alloyed with nickel thousands of years previously.įast forward several millennia to the mid-1800s, and metallurgists discovered that adding chromium to iron made it more durable and formable for making tools, implements, and other items. One of these ways is by alloying iron with other metals, which humans have been doing and continuously improving on for thousands of years. Since there are very few environments that don't contain some water and oxygen, iron will generally always rust unless measures are taken to protect it. This substance is technically made up of one or more formulations of iron oxide (iron, oxygen, and hydrogen atoms). This happens when the iron reacts chemically with water and oxygen, and it does this spontaneously because of these materials' chemical structures.Īs long as iron, water, and oxygen are present, the rusting will continue until all the iron is consumed and become the flaky or powdery bright orange substance with which we're all familiar.

Iron is the largest component of stainless steels, but everyone has seen that it only takes water or damp air to make it rust and break down.

#DOES 316 STAINLESS STEEL RUST SOFTWARE#

Paperless Process Recorder & Cloud Software.Temperature Gauges, Transmitters & RTD Components.Streamline In-Line Filters and Strainers.View All Tubing, Fittings, Installation.

0 kommentar(er)

0 kommentar(er)